Tilbrook motorcycles: Remarkable Rex Tilbrook

By Jim Scaysbrook with considerable input from Alan Wallis O.A.M.

There are more than 200 Australian motorcycle manufacturers scattered in the annals of history, stretching back to the earliest days of motorised transport, alas, now all gone. Perhaps the last was the Tilbrook, the work of a man with a remarkable mind.

Rex Patterson Tilbrook was a man of relentless ambition. A gifted engineer, Rex’s probing mind was always searching for a better way; a more efficient means to manufacture; a breakthrough in design. Like many of his ilk, Rex could also be a prickly character when it suited him.

Born in 1915, Rex was up to his elbows in engines from his early teens, and by the age of 16 had saved enough to acquire a chain-driven Frazer Nash sports car. He had visions of competing in the vehicle in local events, but quickly became focussed on a bigger picture. England, he reckoned, was the place for an aspiring young racing driver and engine designer to be. At the age of 18, he sold the car and booked a passage to Britain, arriving in early 1933 with high hopes of landing a job at the Fraser Nash factory at Brooklands in Surrey. With no such jobs on offer, he found employment at the neighbouring Hawker and Vickers aircraft factories which were also located within the massive Brooklands bowl – the heart of British motor sport.

The place was a hive of activity and manna for a wide-eyed young lad with motor racing in his veins. He soon befriended the owner of a Lea Francis racing car and struck a deal whereby he maintained the car in return for an occasional outing on the fearsome banked track. His fame as a tuner and fabricator spread rapidly, to the point that he took a lease on a vacant building and opened his own workshop, making the specialised exhaust systems and silencers required by the stringent local noise regulations. Yes, noise was an issue, even way back then. His clientele included many top riders and drivers, among them the flamboyant Scottish rider, Fergus Anderson.

Disaster struck in early 1938 when a broken acetylene gauge caused a fire that completely destroyed the workshop. Faced with the choice of rebuilding or bailing out, and with war clouds gathering, Rex chose the latter. With his Brooklands experience, he had plans of setting up in motorcycle manufacturing back in South Australia. Before sailing for home however, he travelled to several ‘continental circus’ race meetings with Fergus Anderson and multiple Brooklands record holder Dennis Minett, typically cutting his run late and catching one of the last boats to leave Genoa before the outbreak of hostilities.

Left: The Dandaloo Sidecar. Right: A Tilbrook Double Adult sidecar mounted on a B33 BSA.

Hanging out the shingle

Back in Adelaide, Rex Tilbrook’s skills were utilised by the war effort in the munitions industry, but when peace returned Rex’s mind once again swung to making motorcycles. In a shed in the back yard of his home in the Adelaide suburb of Kensington Park, he produced the first in a long line of accessories – a universal pillion footrest. By 1947 business was ticking over sufficiently for him to expand to a proper workshop in the same suburb, where he produced a greater range of motorcycle components as well as the first of the stunning Tilbrook sidecars. These unique creations featured a lightweight tubular chassis with torsion bar suspension carrying a stressed metal skin body mounted on tension springs.

The first Tilbrook motorcycle; constructed during the Adelaide Exhibition of 1947.

The dream of producing his own motorcycle still consumed Rex, and the 1947 Adelaide Exhibition, which ran from March 21st to May 17th, gave him the chance to do so. Rather than build a prototype in secret, Rex went public. He took a stand at the exhibition, set it up as an open workshop, and during the 54 days of the show’s duration, the first Tilbrook was constructed. The engine was based on a pre-war 250cc Zundapp, with castings made locally and machined on his stand. It featured an aluminium-alloy cylinder head with a flat-top piston, with a ten-port arrangement. The ignition coil, condenser, voltage regulator, cut-out and complete generator assembly were all housed in a neat compartment on the right hand side of the motor. The high-output 20-amp generator eliminated the major bugbear of coil-ignition systems by enabling the engine to be started with a flat battery. The crankshaft was supported by three main bearings with a white-metal big end bearing. Primary drive was by duplex chain to a three-speed gearbox with a positive-stop foot-change. The engine was a complete running unit in 28 days. Rex’s own design of pneumatic front forks used air pressure to vary the travel. In contrast to the usual brazed-up frames, the new Tilbrook’s chassis was all-welded, with the top tubes wrapped around the aluminium petrol tank in Coventry Eagle and Cotton style. Tilbrook claimed the only English parts in the entire motorcycle were the ball races and the primary and secondary chains. With the exception of the spark plug, the rest of the bike, including the ignition system, was made in South Australia. The complete machine was started up and ridden from the show, and still exists in the hands of Rex’s family. Plans were announced for a production run beginning in 1948, with the option of rigid or sprung frames, but it soon became apparent that mass-producing the 250cc engine was a far more expensive proposition that had originally been thought. The Tilbrook factory was kept busy churning out its accessory range as well as the increasingly popular sidecars in their various styles.

Taking to the track

To showcase his growing range of products, Rex decided to build himself a racing 125cc machine, and three were constructed prior to 1950. Evidence of Moto Guzzi design features could be seen in the racers, such as the radial arm front forks with friction dampers. The 125cc engines were loosely based on the pre-war Villiers Y-port barrel, but with bore and stroke altered to 52 x 58mm. The methanol-fuelled power plant sported a two-staged induction system through Amal TT carburettors; the smaller one-inch unit opening fully at half throttle and the 1 3/16-inch unit taking over from there. Ignition came from a chain-driven BTH magneto running at half engine speed. The heavily revised barrel featured two inlet, two exhaust and four transfer ports, with useful power between 5,500 and 8,400 rpm – good enough for a top speed of 90 mph. The single-loop frame sported Rex’s own design of cantilever suspension, with the spring units located beneath the 4-speed Tilbrook gearbox and damping by Andre friction units. The handsome alloy fuel tank doubled as a fairing/front number plate. The front forks had no conventional top yoke, with the solid legs finishing at the bottom yoke. At race meetings, the immaculate red bikes were accompanied by mechanics dressed in blue Italian-style overalls, decorated with Rex’s three-pointed star emblem.

The racers were ridden by a variety of noted competitors including multi Australian champion Maurie Quincey, who gave the marque its competition debut at Fisherman’s Bend, Melbourne, on Boxing Day 1948. Other regular riders included Rex himself, Tilbrook employee and Rex’s close friend Alan Wallis, and future multi ISDT gold medallist Tim Gibbes.

Production becomes a reality

With the racing team enjoying qualified success, Rex once again turned his attention to constructing a road motorcycle of his own design. In true style, Rex continuously leaked details of his ‘secret Australian motorcycle’ to the press to the point that a wave of enthusiastic publicity preceded the arrival of the first production model - chassis number 4 (1-3 were the 125 racers). For once, practicality had triumphed over passion, and Rex abandoned plans to produce his own engine. He imported a pair of German Ilo 125cc engines but future delivery could not be guaranteed so he opted for the ubiquitous 125 and 197cc Villiers units. Apart from the engine and gearbox however, virtually everything else was produced in house – even the nuts and bolts!

One of the production models, a 1950 197cc.

Inside the Tilbrook factory were individual sections for machining, fabric and leather trim, tube bending, plating and polishing and the paint shop which applied the lustrous deep red enamel that adorned all the products. In August 1950, the first production roadster, a 197cc model, was handed over to proud owner Alan Wallis by the South Australian Minister for Roads, Sir Malcolm MacIntosh in a ceremony also attended by the Commissioner of Police and several federal parliamentarians. During the next five years, the machine covered 98,000 miles before being mothballed for 36 years. In 1991, Wallis restored the machine and still uses it regularly in vintage rallies.

The production Tilbrook featured an exceptionally large four-gallon petrol tank to allow for vast distances to be covered between fuel stops, and a large flared front mudguard to protect the rider from mud and road grime from the crude roads of the time. In contrast to the puny brakes fitted to most of the British Ultra-lightweights, the Tilbrook employed handsome and functional full-width finned aluminium hubs with shrunk-in cast iron lining and 37 mm width shoes.

Alan Wallis recalls, “All models had steering dampers, generally an optional extra on larger machines and virtually unavailable on smaller models, and all had chrome plated tank racks to protect the paint if the rider wished to carry a parcel or bag on the tank. Whereas alternative lightweights had d-shaped speedometers, the Tilbrook was fitted with an 80 m.p.h. instrument having an odometer and trip meter mounted above the headlamp in an easy to read position. Under the press-stud fixed seat pad was a capacious compartment to house the battery, tool roll and puncture repair kit, as well as any spares the owner may have thought were necessary. The tool roll consisted of sufficient spanners to completely dismantle and reassemble the machine and included special tools made by the factory for the wheel nuts, swinging arm pivots, spark plug, exhaust pipe flange and head stem ball race lock ring. A tyre pump was provided and this fitted on spigots under the seat/mudguard assembly. Aluminum castings were supplied by a small foundry near the factory and footrest rubbers and seat inserts moulded by S.A. Rubber Mills (now Bridgestone) using dies made at the Tilbrook factory.

The 1956 Tilbrook prototype which never went into production.

In all, around 55 complete road machines were constructed up till 1956, the final example being readied for the Royal Adelaide Show of that year. This version departed significantly from earlier models in that it featured a twin-loop frame with a conventional swinging arm rear suspension and Girling shock absorbers. The most striking feature was the all-enclosing bodywork which covered the petrol tank and carried the seat and battery/toolbox compartment. By this stage however, the motorcycle trade in Australia was in a seemingly terminal state and the new design never went into full production. The prototype survived however and passed into the hands of noted restorer Ralph Datlin.

A Tom Thumb sidecar hitched to a 197cc Tilbrook.

In reality, the motorcycle part of the business was minute compared to the sidecar production. 1,500 units were produced for both the home and export markets, ranging from the tiny 26 kg Tom Thumb version that was specially designed for lightweight motorcycles to the Dandaloo (aboriginal for ‘thing of grace’). This latter model was available as either a single or dual seater, with rubber bush mounting to insulate the sidecar from the vibrations of the motorcycle. Passenger enjoyed a plush ride, with the seat and backrest formed as a single unit, pivoted on rubber bushes and suspended on coil springs. Even after the closure of the engineering business in 1976, Rex continued to supply parts for sidecars, and even built the odd complete unit to special order.

The revolutionary but unsuccessful rotary valve Tilbrook racer.

The sporting heritage continues

Despite the economic pressures of road bike production, Rex never lost his passion for racing. The three ‘works’ 125 two-strokes were continually modified, and a further five built for customer orders. Always searching for the competitive edge, Rex conceived his most radical design in the form of a 125cc rotary valve racer. Based on Villiers crankcases and using the standard 62mm stroke, the rotary engine had a hardened and ground crankshaft driving a train of gears in a handsome casting on the right hand side. Atop the barrel sat Tilbrook’s version of a twin rotary valve head, with the valves rotating at one-quarter engine speed. The rotary valve concept itself was not new, but the twin problems of sealing the valves and the combustion chamber, and of lubricating the valves usually proved insurmountable. With clearances so critical, varying degrees of expansion among the various components usually resulted in either seizures or loss of sealing, but Tilbrook’s answer was to attach the barrel to the head using a spring loaded technique. The idea certainly worked, with the engine spinning to 12,000 revs with useable power from 8,000. As soon as the rotary engine was completed it was installed in the chassis of Rex’s two-stroke racer and he took off for a test run up the main street outside the factory! Within minutes he was back, declaring the project a failure since it offered no appreciable advantage. Rex totally lost interest in the project and the rotary was never raced in anger. Fortunately, the unique machine survives in totally original form in the hands of Rex’s son-in-law Tom Johnston.

The last Tilbrook; the 125cc GP racer.

In 1989, when the Australian Grand Prix at Phillip Island finally became part of the world championship, Rex decided to have a crack at the 125 class and built a typically-innovative 125 contender powered by a Yamaha engine and entered for future Australian Superbike Champion Steve Martin. The machine however, was hopelessly outclassed in the highly developed GP field, and was withdrawn from the race. The 125 was taken back to Adelaide and all-but forgotten, but recently was acquired by Lyndon Tilbrook in Canberra, who has fitted a Villiers engine to the chassis.

As the motorcycle market continued to diminish, Tilbrook still produced sidecars and accessories, but gradually switched over to contract engineering work, making, among other things, tables and chairs. The firm finally closed down in 1976.

The old Tilbrook factory at 64 Bridge Street Kensington has been fully restored to its original guise of the Rising Sun Inn, and is today a very popular restaurant in this leafy Adelaide suburb. Adorning the walls are several photographs of the premises when it produced motorcycles and sidecars rather than haute cuisine.

Indeed, 46 years after the factory ceased motorcycle production, the Tilbrook marque is still extremely well represented. Numerous solo machines and hundreds of the superbly-built sidecars still swell the ranks on classic rallies. The fondness with which the brand is remembered is largely due to the efforts of Alan Wallis, Rex’s great friend and former employee. As well as being the marque expert and a sought-after speaker on the subject, Alan served many years as an administrator at the top level of the sport and received an Order of Australia medal for his work.

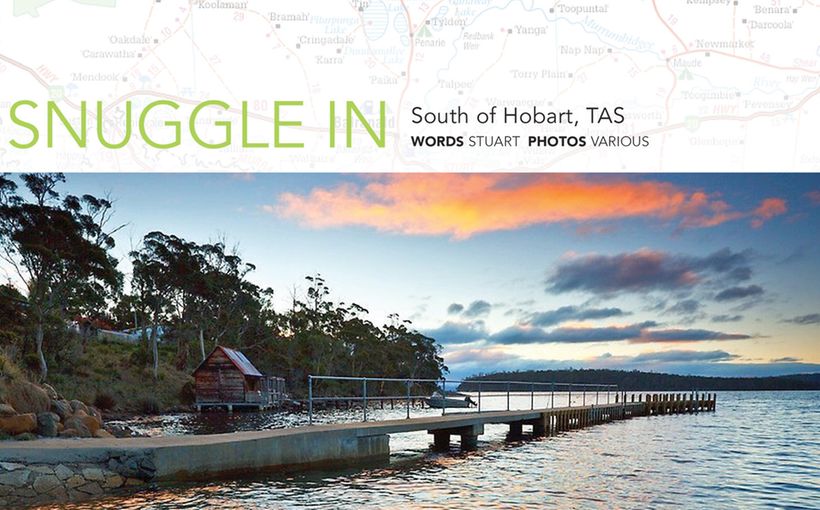

Apart from enjoying the contents of his crammed workshop, Rex and his wife Dorothy made a complete break from the business that had been their lives for 30 years and re-established themselves at the seaside town of Victor Harbour, south of Adelaide in 1976. There they built a prominent restaurant, The Whalers Haven, and a museum that housed artefacts from the whaling heritage of the area. Far from taking it easy, Rex became a significant figure in the district, heading several local associations, leading the project that rescued the historic Victor Harbour railway from demolition, and even standing for Parliament at one stage. Rex died of leukaemia on December 3rd, 1997.